INSULATED HOT PRODUCTS

Our equipment is engineered to perform and most importantly – built to last.

Previous

Next

Industry Leading Heat Retention

Advance Engineered Products builds a number of of Insulated units in a range of sizes. Models include:

- Double Conical

- Tridem Semi Trailers

- B-Trains

- Supertrains

All of Advances trailers are engineered for the toughest conditions and include designs, manufacturing techniques, materials and components that work to produce trailers for the tough conditions our customers operate in.

- Designs built and tested with customers for over 30 years

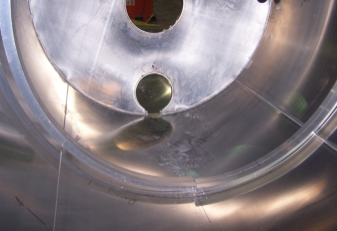

- Corrosion Resistant Designs include: Flangeless Baffles, Heavy Duty 1 Piece Machined Aluminum Pan Sumps,

- Tough Durable Designs: Full ¼” Aluminum barrel, Fully Welded Collars and Outriggers

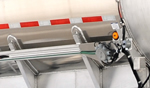

- Ease of Operation and Service: Side mounted extruded aluminum wiring harness for ease of access and trouble shooting

- Service Network: Factory supported service branches for expert certified repairs

- Specialty Parts Support: Service branches with large selection of specialty Tank Trailer parts

- Warranty Coverage: Three year warranty

Advance’s Insulated Trailers stand apart from the competition.

Designed and tested for extreme operations in Canadian winter conditions and rough road operations.

Specialty and Unique Engineering and Manufacturing features include:

- Leading heat retention capability

Guaranteed at 3 Degrees F per hour heat loss, and measured to less than 1 Degree per hour. - Buckle proof shell alignment

Shell uniformity and weld seam placement engineered and manufactured to ensure buckle proof operations. - Fully Insulated Designs

Insulated frames and isolated heat paths are insulated and sealed to ensure heat retention and longevity. - 400F Degree Exposure Design

All under jacket materials are rated for a full 400F Degree capability. Product goes in hot and stays hot. - Outer Jacket Compensating Design

Outer jacket “slide” design accommodates tanks expansion and detraction cycles during load/unload. - Standard Rollover Protection

Super duty rollover protection and spill prevention design and devices included and standard in insulated units.

Advance’s Insulated Trailers with industry leading heat retention and operations capabilities help enable:

- Hotter load transfers

- Faster unload times in extreme cold conditions

- Longer trip capabilities

DEF - 2024 43,000L Insulated Stainless Steel B-Train

Insulated Hot-Product B-Train

49,000L/2C Aluminum TC406 Hot Product B-train

Insulated Hot-Product

DEF Insulated Tank Trailer

Insulated Hot-Product

Insulated Hot-Product

49,000 Litre, 2 Compartment Insulated Aluminum B Train Tank Trailer

7000 USG Insualted Tandem Semi

Insulated Tandem Tank Trailer

Share

Share on facebook

Facebook

Share on twitter

Twitter

Share on linkedin

LinkedIn

Share on email

Email

Engineered for the Toughest Conditions.

Send me more information

Call Now for More Information

SALES ENQUIRIES

1-800-332-8385